VAN GEERT ART FOUNDRY takes charge of the entire craft process, from idea to installation. This process always takes place in collaboration with and under the supervision of the client or the artist.

Together with us, the artist can carry out certain stages of the process themselves, while benefiting from the support they require from our team of experienced and motivated craftsmen.

Find out how we work on this page.

Jo Van Geert

Contact us and we’ll make an appointment to discuss your idea or creation, or send us the information we need to get started.

Do you have a model, sculpture or object in wax, plaster, plastiline, clay or another material? You can bring it to our foundry. A negative mould will then be made from the original.

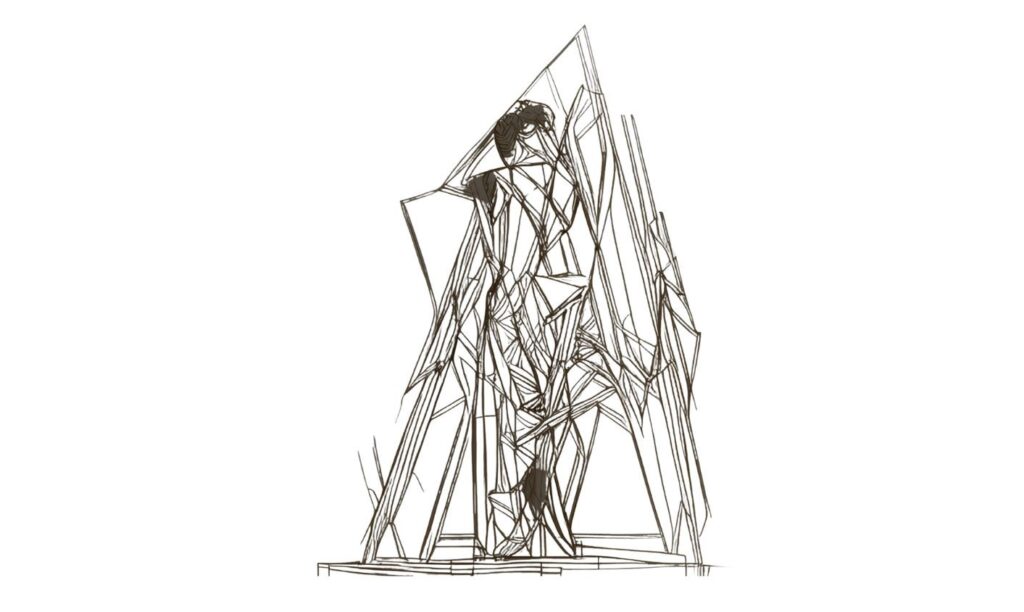

Based on your idea, a photo or a simple sketch, the team at the art foundry can produce the creation in bronze. The drawing is created in 3D on a real scale, in polystyrene or by 3D printing.

A negative mould is a print of your original model in high quality silicone, with a hard epoxy backing to support the shape. This mould can be used several times. Large moulds can be made on site.

The negative mould is carefully coated with wax to reproduce every minute detail and texture of the original. The hollow wax model is a copy of the original and of what will later be cast in bronze. The artist or customer signs and approves the wax model.

Once the waxwork has been completed and viewed by the artist we attach the spruing system. Spruing is the attachment of wax bars and a wax cup that will become the channels for the bronze to flow through when the piece is poured.

Spruing the piece well is essential for a good casting. Every piece is assessed based on complexity and we have a keen eye for sprue design to ensure a great casting.

The bronze ingots are melted at 1200°C. The hot bronze mass is then poured into the refractory mould. After cooling, the sculpture is removed from the mould: the refractory mould is broken to release the untreated bronze casting. The bronze sculpture is cleaned of all remnants of the refractory mould.

Casting ducts and vents are cut out and burrs are ground away. Cavities and joints are welded and touched up invisibly.

This is the art of metal chasing, which involves carefully and meticulously working the surface of the bronze using files, abrasives and other tools.

The sculpture is finished with a coat of patina of your choice (patination). The patineur gives tailor-made advice and implements the artist’s vision.

The sculpture is then covered with a layer of wax to protect the patina and slow down oxidation.

Instead of patinating or colouring the sculpture, the sculpture can be polished to bring out the yellow-pink colour of the bronze and give it more sparkle.

On request, the bronze sculpture can be transported and/or installed by us, in Belgium or abroad. A pedestal can be supplied.

Under the direction of master bronze founder Jo Van Geert, the creations and ideas of Belgian and foreign artists are translated into bronze works that stand the test of time and have an impact on their environment.

Copyright 2024© All rights Reserved. Design by Webite – privacy statement – cookie policy